Periodic Plant Operator Training is Crucial

Process Heating System Operators Require Regular Training for Safe Operations.

It's a widely recognized fact that operator errors are a leading cause of many plant shutdowns and safety incidents. Plant operators play a pivotal role in various aspects of plant operations and performance. Consistent operator training helps ensure that operators are proficient and safe in managing equipment. A key component of running process heating equipment effectively involves regular operator maintenance training.

hbspt.cta.load(379517, 'aa5b43aa-b619-4484-9a77-acd0076e89b8', {});

The Case for Maintenance Training

Improper system maintenance conducted by inadequately trained staff can create hazardous operating conditions that may result in workplace incidents causing injury or even fatalities. For example, a local industrial company in Nebraska started experiencing operational problems with their steam generator. Without fully comprehending the root causes, their operators kept resetting the generator but saw no improvements.

Ultimately, the generator exploded, blowing off the entire top portion. The natural gas fuel train and piping to the burner were also severely damaged due to this incident. Fortunately, no one was injured, but it could have easily turned tragic. Following the explosion, the operator reached out to Sigma Thermal; our technicians diagnosed the problem over the phone and guided them through steps to restore their system. Had the operator known how to correctly troubleshoot the equipment, this event might have been avoided.

How Often Should Operators Be Trained?

What happens when an operator unexpectedly leaves or retires from a manufacturing facility? In numerous industrial sectors, the lack of experienced operators and the prevalence of high turnover often lead to a knowledge gap in many facilities. It can be challenging to determine whether current operators possess the necessary skills to fulfill their duties safely. However, regular operator training ensures that all operators stay updated and informed about every aspect of the equipment, including maintenance.

What happens when an operator unexpectedly leaves or retires from a manufacturing facility? In numerous industrial sectors, the lack of experienced operators and the prevalence of high turnover often lead to a knowledge gap in many facilities. It can be challenging to determine whether current operators possess the necessary skills to fulfill their duties safely. However, regular operator training ensures that all operators stay updated and informed about every aspect of the equipment, including maintenance.

Depending on the complexity of the system in question and its operational frequency, the frequency of operation, safety, and maintenance training can vary. Original equipment manufacturers (OEMs) of process heating systems usually suggest that onsite personnel receive training annually. These training sessions can range from a single day to a full week, depending on the system's complexity. When is the optimal time to schedule these training sessions? To cut costs, training sessions should ideally coincide with routine system audits or maintenance visits.

Time and budget constraints can affect a company’s decision regarding how frequently training should occur. It’s not unusual for key personnel to have limited training due to time constraints, nor is it rare for companies to delay, cancel, or skip training to avoid the costs related to operator downtime. Ultimately, the potential losses in terms of time and money that could result from an accident should outweigh the costs associated with training.

What Should Training Sessions Include?

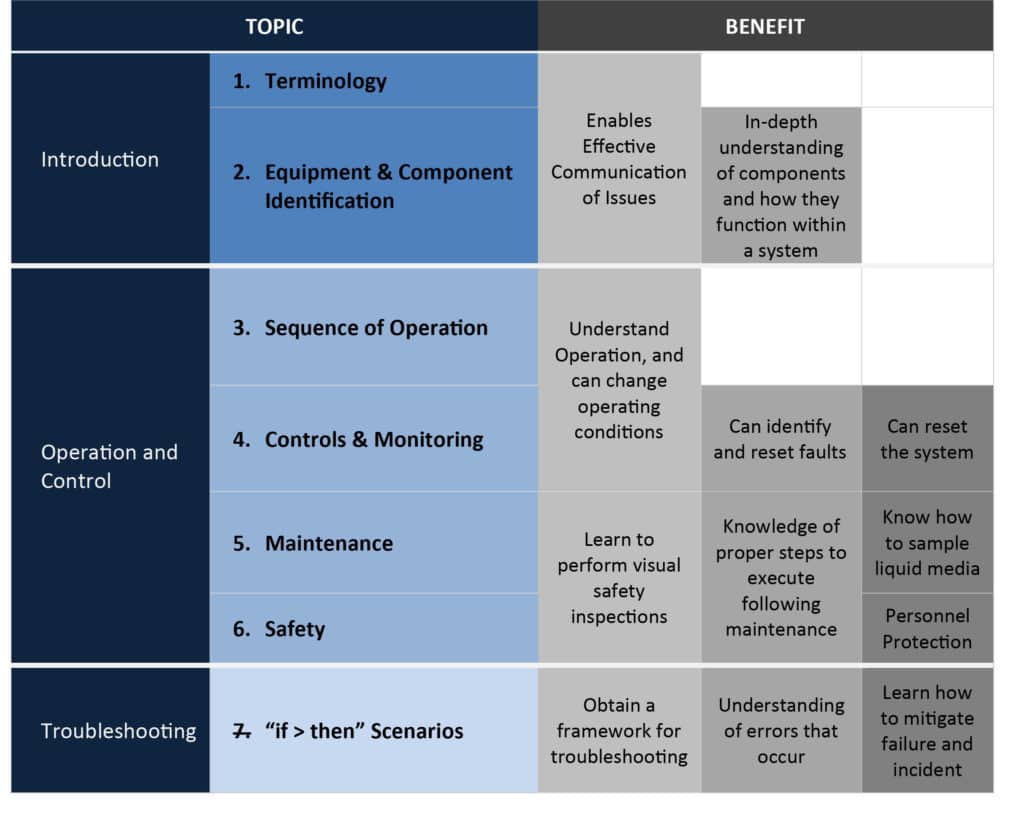

Typically, training sessions should cover system introductions, operation and control summaries, safety, and hands-on troubleshooting exercises.

Typically, training sessions should cover system introductions, operation and control summaries, safety, and hands-on troubleshooting exercises.

In regards to Process Heating Systems, during an introduction, personnel first learn all relevant terminology and are trained to recognize basic equipment and components. This introduction allows them to develop a deeper understanding of how the system functions, which will help them communicate system issues more effectively during support calls later on.

Operation and control sessions cover startup and shutdown performance expectations and expectations for the entire process. Operators are also trained to perform visual safety inspections, an essential function for safe operation. Additionally, all training includes a series of “if > then†scenarios; it’s highly recommended to include live demonstrations of actual faults whenever possible. “If > then†scenarios provide an excellent framework for troubleshooting and mitigation efforts and help personnel better understand the system.

Table 1A

Common Training Topics – Process Heating Systems

It should be noted that if high-level formal operator training is required, it should incorporate both classroom sessions and an exhaustive on-site walkthrough. Emphasis should be placed on the on-site walkthrough, as this is where operation and maintenance personnel can realistically become familiar or refreshed with the equipment/system.

Requirements for Effective Training

Whether training is provided by the original equipment manufacturer or by internal personnel, there are several factors that must be present for training sessions to be productive and worthwhile:

- Motivated Employees

- Real-life Hands-On Scenarios / Visuals

- Repetition

- Sufficient, Dedicated, Quiet Training Time

- Concise Training Sessions (maximum of 1-2 hours per session)

- Momentum from Upper Management

Need to Schedule Operator Training?

Sigma Thermal offers annual training and maintenance services to owners of industrial process heating equipment and systems. As part of our commitment to our customers' success, Sigma Thermal developed a Total Customer Care Program (TCCP) which combines these services for new and existing clients alike.

Sigma Thermal offers annual training and maintenance services to owners of industrial process heating equipment and systems. As part of our commitment to our customers' success, Sigma Thermal developed a Total Customer Care Program (TCCP) which combines these services for new and existing clients alike.

Program members can pre-schedule annual appointments, and Sigma technicians will travel on-site for a comprehensive visit that can include training, system inspection, maintenance assistance, efficiency evaluations, and more.

Sign up for Sigma Thermal’s Total Customer Care Program today.

Contact Us

For more information about training and Sigma’s TCCP maintenance plan, contact us at 678-616-2820, or

Â

Mini-Truck,Changan Star Card Plus,Changan Star Card Luxury,Changan Shenqi T30 Standard Car

TRUMPET CAR , https://www.trumpetcar.com