Proper gearbox alignment is vital for optimal machine performance, extending equipment life, preventing costly repairs, enhancing energy efficiency, and ensuring workplace safety. However, misalignment often goes unnoticed until it leads to significant issues. In this article, we’ll explore what gearbox misalignment is, why it happens, and how to prevent it.

Understanding Gearbox Alignment and Its Importance

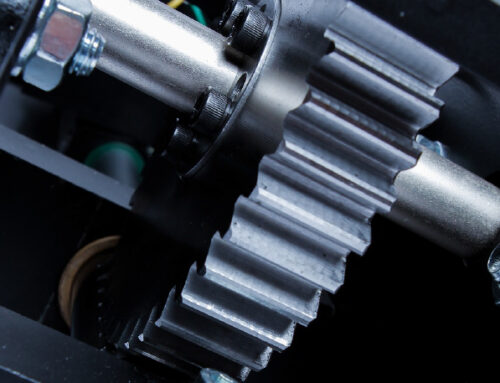

To function effectively, a gearbox must be precisely aligned with its connected components, including the motor and other moving parts like conveyors or crushers. This ensures that the input and output shafts of the gearbox are perfectly aligned with the corresponding drive units. When these components aren't aligned, the gearbox becomes misaligned. Proper alignment is key to preventing unnecessary wear and tear, avoiding unexpected breakdowns, and maintaining consistent performance.

Why Misalignment Matters

Misalignment places undue stress on critical components like shafts and couplings, accelerating wear and tear and increasing the risk of catastrophic failure. Additionally, misalignment can reduce energy efficiency and create unsafe working conditions. Therefore, understanding the different types of misalignment and how to detect them is crucial.

Common Causes of Gearbox Misalignment

Angular Misalignment

Angular misalignment occurs when the input and output shafts of the gearbox are not perfectly aligned angularly, creating an angular offset between them. This can happen due to improper installation, manufacturing errors, or physical damage to the gearbox housing.

Potential Causes:

- Improper installation or assembly

- Damage to the gearbox housing or mounting surfaces

- Parallel misalignment of the shafts

- Manufacturing defects

Parallel Misalignment

This type of misalignment arises when the centerlines of the two shafts, intended to be aligned, run parallel but are offset. Parallel misalignment often results from improper shimming during installation or wear and tear on bearings.

Potential Causes:

- Improper shimming

- Worn or damaged bearings

- Defects in gearbox components during manufacturing

Combined Misalignment

Combined misalignment happens when both angular and parallel misalignments occur simultaneously. This can be caused by a variety of factors, including installation errors, foundation settling, and component defects.

Potential Causes:

- Improper shimming

- Worn or damaged bearings

- Installation mistakes

- Floor settling

- Component defects

Thermal Expansion Misalignment

This type of misalignment occurs due to temperature changes that cause connected shafts to expand or contract, shifting them out of alignment. Environmental fluctuations and inadequate consideration of thermal expansion during installation can contribute to this issue.

Potential Causes:

- Temperature variations

- Inadequate thermal expansion planning

- Variations in material properties

Soft Foot

A "soft foot" occurs when a gearbox isn't resting evenly on its mounting base or when one leg is shorter than the others, leading to uneven forces on the gearbox housing. This condition can cause misalignment over time.

Potential Causes:

- Uneven or deteriorated foundation surfaces

- Improper shimming

- Distorted gearbox housing

Resonance-Induced Misalignment

Resonance-induced misalignment happens when the natural frequency of the system aligns with external forces or vibrations, causing amplified oscillations. Poor damping, improper gearbox design, or changes in operating conditions can all contribute to this problem.

Potential Causes:

- Inadequate damping

- Poor gearbox design

- Operating condition changes that trigger resonance

Vibration and Shock Loads

Persistent exposure to high levels of vibration or sudden shock loads can gradually lead to misalignment. Unbalanced rotating parts, worn-out bearings, and insufficient maintenance can exacerbate this issue.

Potential Causes:

- Vibration transmitted from other machinery

- Unbalanced rotating parts

- Worn-out components like bearings

- Poor maintenance practices

Five Tips to Prevent Common Misalignment Issues

Preventing misalignment starts with careful attention to detail during installation and regular maintenance. Here are five practical tips:

1) Proper Installation and Mounting

Follow the manufacturer's guidelines for installation and ensure precise alignment of the gearbox and connected components. Small errors during installation can lead to big problems down the road.

2) Replace Worn or Damaged Components

Regularly inspect and replace worn or damaged parts like bearings, seals, and gears. Our extensive inventory of new and used Falk parts is available, or contact us for help sourcing specific components.

3) Schedule Routine Maintenance

Partnering with a professional gearbox repair and renewal specialist is one of the easiest ways to avoid common misalignment issues. Regular maintenance checks can catch problems before they escalate.

4) Store Gearboxes Properly

Shocks and falls can cause internal damage or misalignment. Follow our storage tips to ensure your Falk gearboxes remain in optimal condition when not in use.

5) Conduct Regular Alignment Checks

Laser alignment systems are a reliable way to ensure gearbox shafts are properly aligned. These systems use laser units mounted across the coupling to measure and correct misalignment issues.

Contact Us for Gearbox Repair and Maintenance

By prioritizing proper alignment and implementing preventive maintenance practices, you can enhance the reliability and productivity of your machinery while minimizing operational costs and risks. Learn more about our Falk gearbox repair and renewal services or reach out to us for additional support. Our experts are available 24/7 to address your specific needs.

Share This Article

Air Hose,Flexible Connection Pipe,Rubber Coolant Hose,Epdm Rubber Braided Hose

Xingtai City Xinyuan Sitong Auto Parts Co.,Ltd. , https://www.xystrubber.com